Brovi One Inorganic

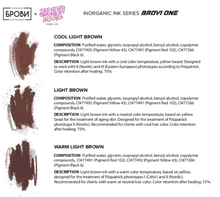

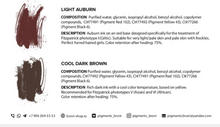

Inorganic BROVI ONE contains 50% less black pigment than other inks.

A unique homogenization (mixing) technology allows us to get stable brown ink with significantly less use of carbon black (Carbon Black CI#77266).

Modern, purified from benzo[a]pyrene and safe Carbon Black (CI#77266 — Pigment Black 7) and pure, micronized iron oxides are used in production.

The cosmetic base is assembled on purified water (without salts and impurities) with the addition of isopropyl and benzyl alcohols — in such a mixture no bacteria can survive. These alcohols increase the sterility of the ink, prevent inflammatory processes in the skin and make it extremely safe for the human body.

The ink does not dry out. This property is provided by copolymer compounds. Suspension property modifiers ensure ease of working with ink and improve the penetration of pigment particles into the skin.

The ink is easy to wash off the skin and easy to implant into the skin. It does not cause excessive irritation. The sedimentation process of pigment particles (their settling to the bottom of the bottle) is minimized, but not excluded. After a light shake of the bottle, the ink is normalized and is ready to be used.